Dimensional Control automet System

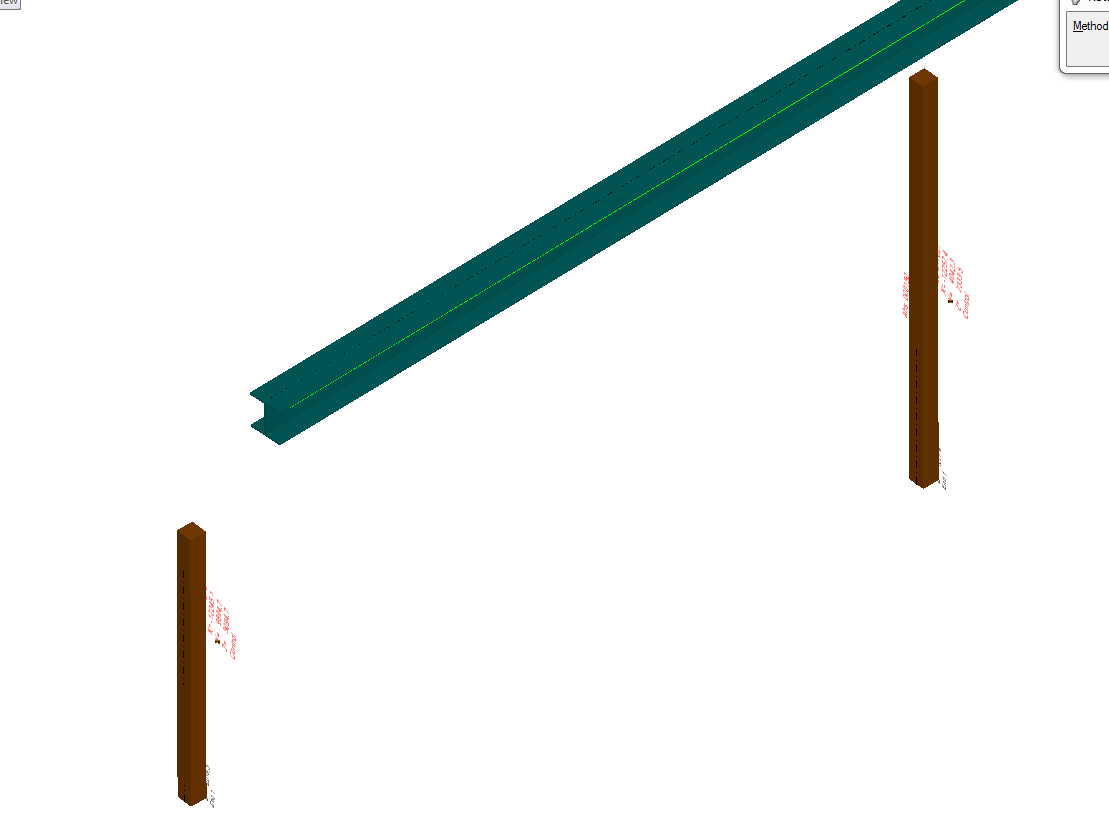

The traditional theodolite is still the best tool for a lot of dimensional control work.

We use it to collect as-built data from site, establish control systems and measure equipment such as beams,

flanges and pipe work to sub mm accuracy. To help facilitate this Vinje Industri have purchased an automet system licence,

specialist software designed to work with a Leica theodolite to capture and calculate such data.

Fabrication inspection

Our piping centre in Kristiansand uses a Metronor system to carry out the dimensional checks when a pipe spool is produced

using a piping bending machine but the Metronor system does not have the facility to carry out flange checks, orientate the

spool to a “best fit” position, rotate the spool and produce auto generated drawings like the automet system has.

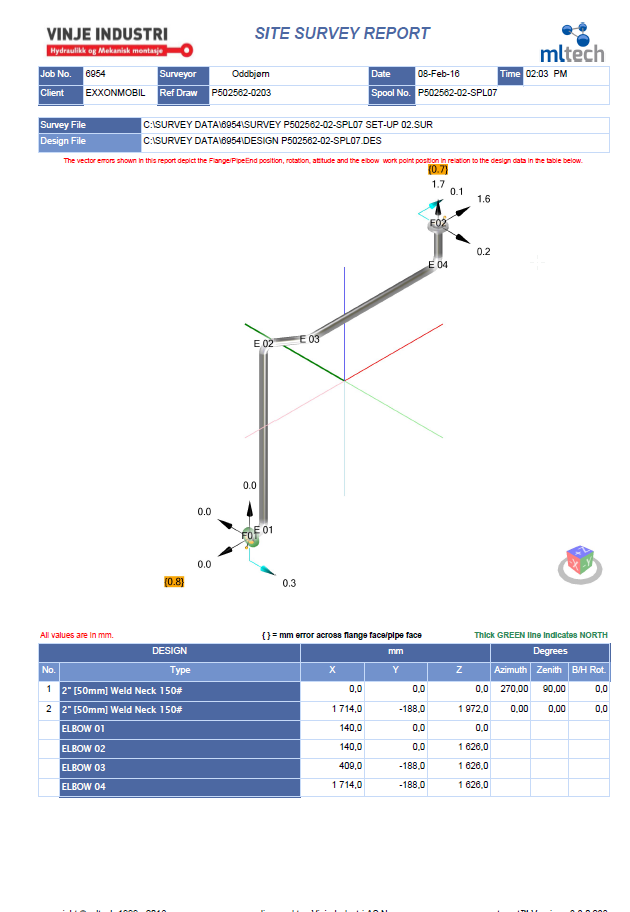

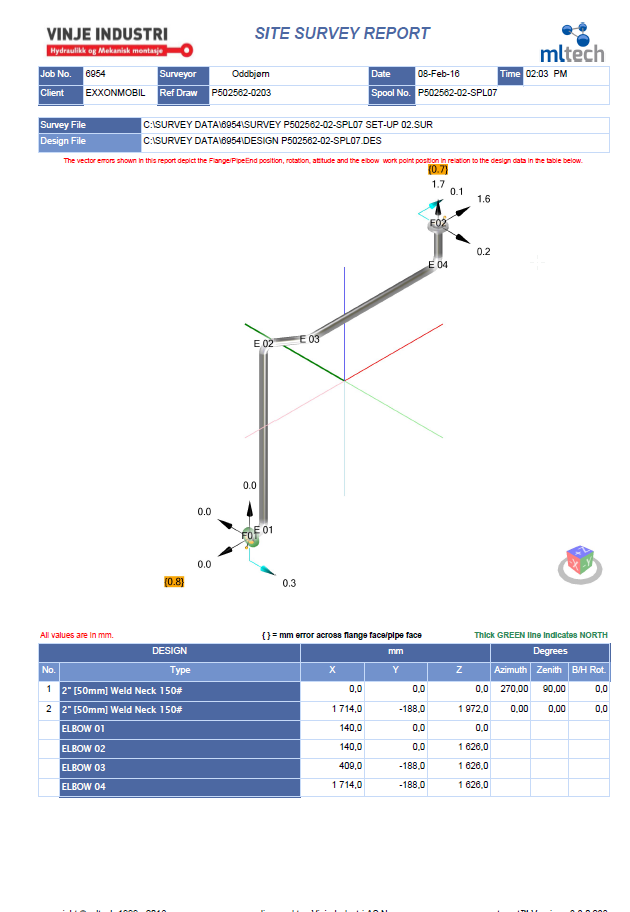

Once a spool has be measured in the fabrication shop using the automet system it can be calculated and a fully drawn vector error report,

with all deviations, produced in around five minutes. This means all work carried out in the shop can be checked straight away. This removes

any danger of not finding mistakes or errors at the pre weld stage. It also allows you to communicate with the fabricator directly and indicate

any repairs which need to be made. All fabrication reports can be exported to pdf complete with all relevant dimensional spool information.

The system is simple to use and easy to learn, focusing on good survey working practice and an emphasis on showing the survey results

in a manner which everyone can understand.

The ease of use allows for people with no survey training or knowledge to learn the system. A knowledge of piping is a large advantage,

making anyone with experience in this area a prime candidate for automet training and use.

Site Survey

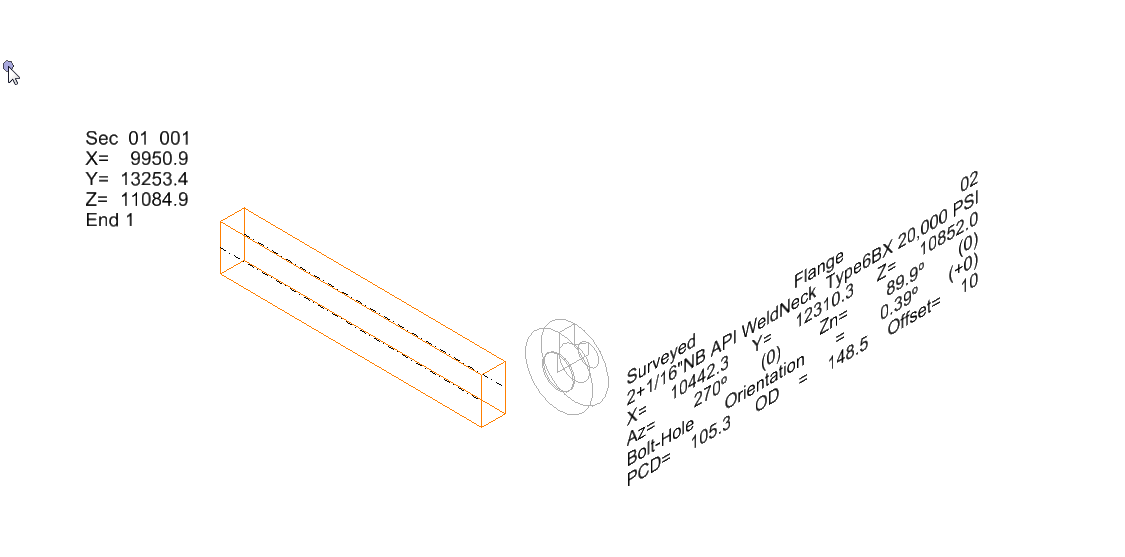

At site, offshore or onshore, when we do scanning or only use the theodolite, Vinje Industries dimensional department always use the automet system to have control of the targets,

flange or tie-in points whenever this is needed. The system gives us the opportunity to provide and check the identification of a flange, for instance what P.C.D and OD size the

flange is, as well as give very accurate location, tilt and bolthole rotation of the flange. This is very important to check because the as-built drawings are not always as the

installed object are. Especially at older installations/plants.

When importing the measured objects into MicroStation we get an accurate 3D presentation of what we have measured. This 3D model can then be imported into many other 3D cad software.

Some key features

- Measure Pipe

- Measure shapes

- Design Pipes

- Translate, Scale and Rotate

- Fab Fit

- Export inspection report to PDF

- Plane fit

- Onboard Coding

Here is some more information regarding the system:

automet™ System

The automet™ pipe & steelwork measurement system has been developed using experience gained over 30 years and is based on current best practice models. This provides a complete and reliable method of replacing existing, or installing new pipe & steelwork without the requirement for hot work, eliminating the risks associated.

A key feature of the software is the capability to provide automated unambiguous reports. This allows for superb consistency and a thorough, traceable audit trail. Put simply, this technology allows you to work productively, and with precision.

Currently the system is being employed in the UK, Norway, USA, Germany, India, South Africa, Australia and UAE by major Oil & Gas companies, engineering and fabrication contractors performing plant and pipework measurements.